MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

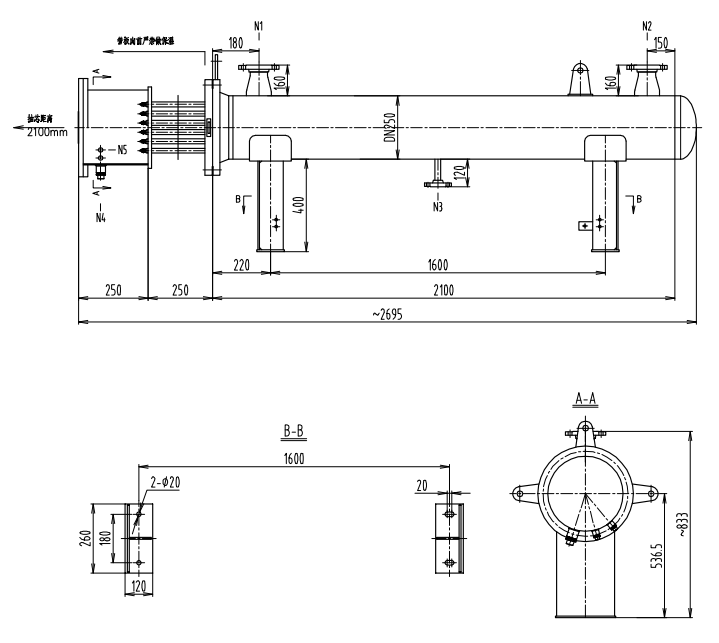

Marine Oil Cooler

Marine Oil Cooler

1. Marine Oil Cooler Preface

This marine oil coolers have been the first choice of coolers for many marine engine and transmission manufacturers. The unique tube stack design manufactured by HI-SEA Marine helps to prevent build up of sediments and growth from occurring within the tubes whilst minimising erosion. For vessels operating in shallow or brackish water, we can also supply the marine oil coolers fitted with our 70/30 CuNi tube stack or a Titanium tube stack to improve the length of operational service of the Oil Cooler. Our larger coolers feature leak detection rings as standard which will enable a maintenance engineer to see a leaking O Ring before the oil and water circuits mix.

2. Marine Oil Cooler Specification

The technical parameter is optional, we can accommodate your requirements, please don’t hesitate to contact us!

Capacity m³

Power supply

Power

Ingress Protection

Ampere

Explosion-proof

Operating fluid

Operating temperature℃

operating pressure

1.85m³/h

AC380V 3φ 50Hz

60KW

IP55

91.2A

ExdIIBT4

Lubricating oil

40-90

0.25MPa

Sea Water Flow - 20 L/min to 800 L/min (Subject to number of tube-side passes)

High pressure designs available upon request

3. Marine Oil Cooler Features

(1) 90/10 Cupro-Nickel tubes as standard and 70/30 Cupro-Nickel or Titanium tubes available for polluted waters(2) Naval Brass tube plates as standard with option for 90/10, 70/30 or Titanium.

(3) Aluminium shells Gun Metal (bronze) headers

(4) Nitrile seals (Viton seal are available for applications where operating temperatures exceed 100ºC)

(5) Quick delivery times available for most products